One of the most popular activities in the Alkek One MakerSpace is 3D Printing. Users create 3D objects that are sometimes works of art, sometimes creative gadgets, and sometimes prototypes of new inventions. The 3D technology has opened the door to all kinds of entrepreneurial endeavors. But the downside of this technology is that it produces a great deal of plastic waste.

This concerned Alkek One’s MakerSpace Night Manager William Cates.

“When I first started and I saw how much waste there was, I was wondering if there was anything we could do because I am really big on no waste and recycling,” Cates said. “I knew other maker spaces had figured a way to clean that up.”

Due to failed or uncollected projects and unused filament at the end of each spool, MakerSpace managers determined that about 20% of the plastic the library had was waste material. But because the plastic would not break down, this waste would just be clogging landfills. While they searched for solutions to this problem, they continued to collect and save their waste plastic.

MakerSpace Supervisor Noah Brock shared that the library owned some of the equipment needed to melt down the plastic and turn it into reusable filament, but they still needed the most expensive piece of machinery, the shredder that would actually grind down the waste plastic so that it could be fed into the filament extruder.

“Someone else that works at the university mentioned that there was an Environmental Services Committee that would fund projects like this,” Brock said. “It’s a student-run organization that funds sustainability projects on campus. We put together a presentation, met with them virtually, and they basically said ‘Ok, you’ve got it!’ on the spot.”

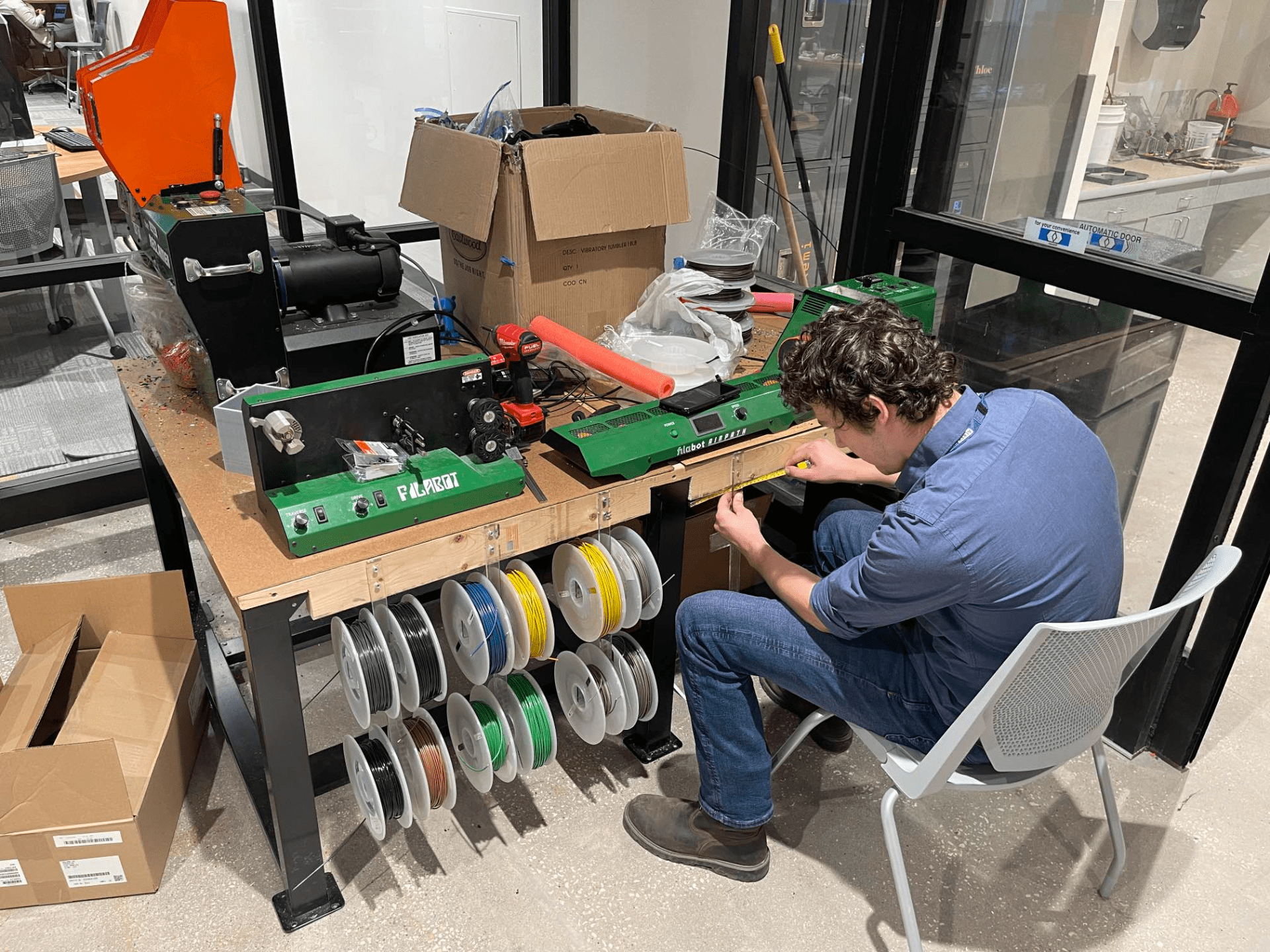

After some trial and error, MakerSpace managers Noah Brock and William Cates enlisted the help of engineering student Tyler Davis who embraced the challenge and eventually was able to figure out how to successfully regrind and extrude 15 spools of reusable plastic, keeping roughly 15 kilograms of plastic out of the landfills to date.

“Tyler, our student employee, was able grind up and recycle almost all of the waste plastic we had collected,” Brock said. “So there is going to be very little waste going forward, maybe like 1%.”

As word has gotten out about the success of the project. Other maker spaces on campus are planning to start donating their 3D printing waste plastic so that the library can recycle it, too.

Using an RFID reader/writer and some custom coding, the team was able to develop their own filament code for the spools so that in the future 3D printing users will be able to select the recycled filament in the appropriate colors for their projects. The 3D printers in the library are free to use, but patrons must pay for the filament. However, the expectation is that the recycled filament will offer an option that is completely free, since the waste filament has already been paid for.

Learn more about equipment and services in the Alkek One MakerSpace from our website.

This article was contributed by University Libraries Marketing and Communications Coordinator Debbie Pitts.